How is SEAJET PellerClean Different from Other Running Gear Coatings?

24 month

24 month

Our patented silicone resin maintains its hydrophobic properties for a prolonged period allowing PellerClean a service life of up to 24 months.

Biocide-free

Biocide-free

PellerClean is biocide-free and safe for the user and the environment compared to biocidal products.

Easy Application

Easy Application

PellerClean comes with an epoxy primer which allows long overcoating interval between the primer and the Silicone finish. This allows flexibility in the application process which makes the application easier.

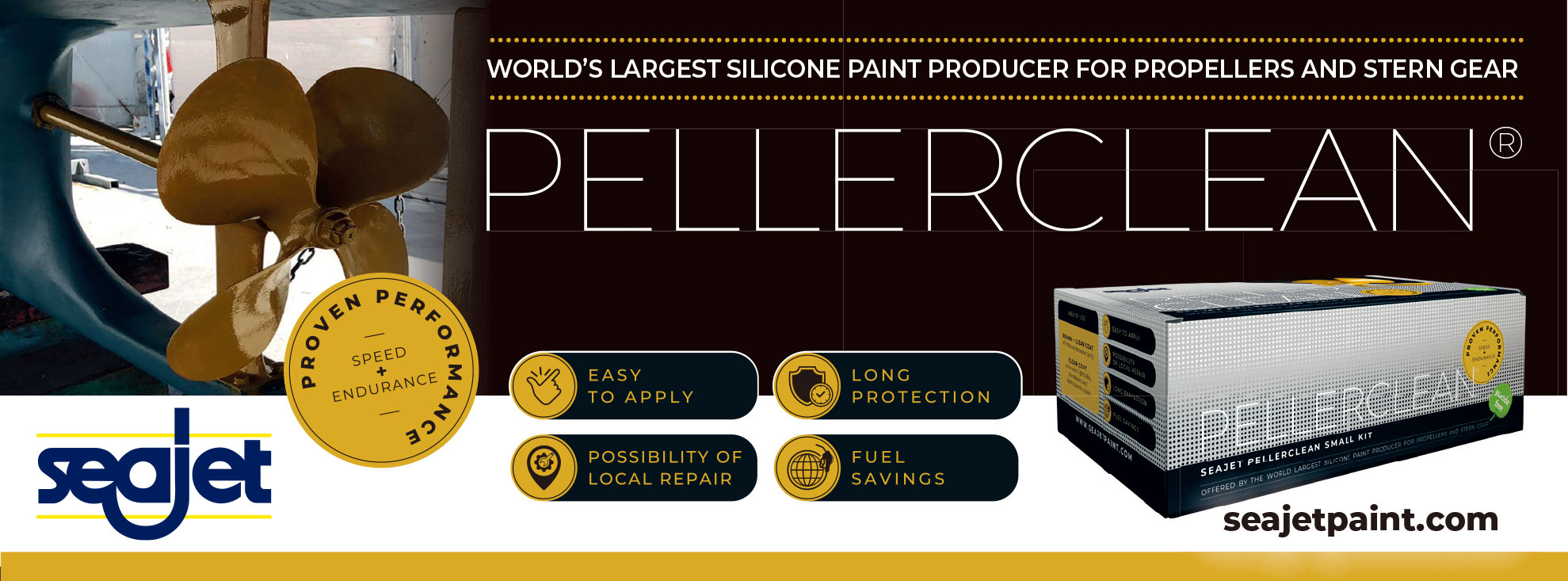

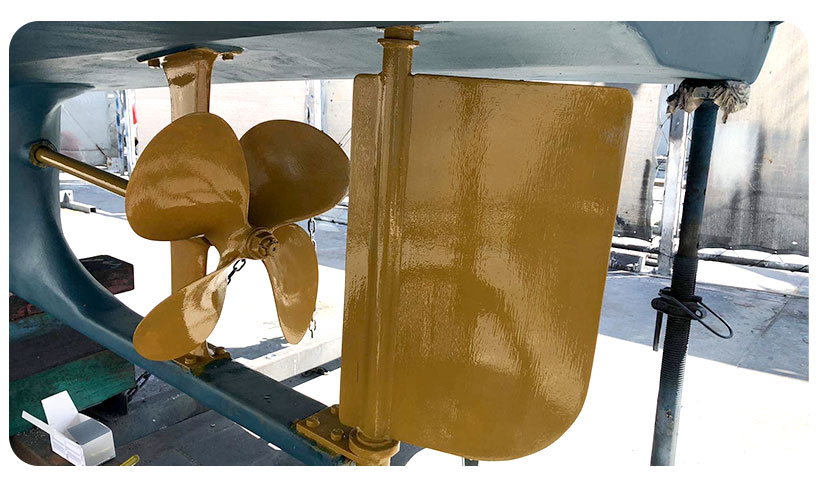

SEAJET PellerClean is a foul release silicone coating for propellers, stern gear, shafts, rudders and trim tabs. This foul release product is environmentally friendly, does not contain biocide and provides long lasting foul-release property in both fresh and saltwater environments. SEAJET PellerClean is designed to withstand up to an average speed of 40 knots. Suitable for DIY use as well as professional use.

- Two-coat, environmentally friendly system

- Two-part zinc chromate free patented epoxy primer with excellent adhesion

- Silicone-based foul-release coating which provides an ultra-smooth, ultra-slippery surface

- Provides long-term protection against fouling in both fresh and saltwater environments.

- Any fouling removes itself from the surface when underway.

- Inactive boats or less than five knots – quick wash or sponging will remove any surface fouling

How to apply SEAJET PELLERCLEAN?

Step1Surface treatment

Remove all contamination and any existing coating from the substrate by using a combination of scraper, abrasive paper, and abrasive pads.

Remove the dust by fresh water washing.

Step2Creating a surface profile

Abrade the substrate using a medium grade abrasive paper (P80, 80 grit, etc.) to create a surface profile.

Rinse the surface with any SEAJET thinner.

After rinsing, do not touch the substrate without wearing gloves to avoid contamination.

Step3Application Primer

Pigments in Pellerclean Primer Base may be settled. Stir until homogeneous.

After mixing the base, add the Pellerclean Primer Hardener and mix thoroughly for 3 minutes.

Apply two coats of Pellerclean Primer on the substrate.

The second coat may be applied immediately after the first.

Maximum overcoating interval between the primers is 7 days. Allow a minimum drying time of 15 minutes, but no longer than 30 minutes, before moving on to step 4.

Step4Application Clear coat

Apply a minimum of two coats of Pellerclean Clear Coat.

The second coat may be applied immediately after the first. To obtain maximum performance, use all Pellerclean Clear Coat provided in the kit.

Repair and recoating

For re-coating existing Pellerclean: If the existing system is intact, you may re-coat after fresh water washing.

Do not apply primer over clear coat. Re-coating may be required annually at high cavitation areas.

To repair damaged areas, follow application instruction steps 1-4.

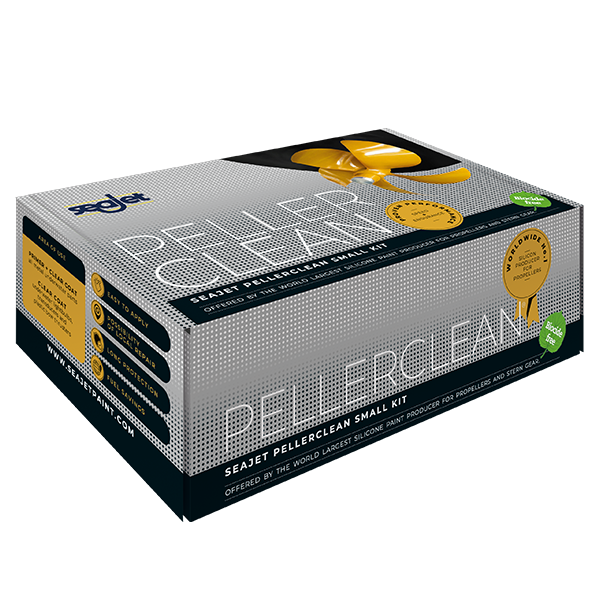

SEAJET PellerClean

| Technical Data | |

|---|---|

| Product name | SEAJET PellerClean |

| Type of product | Foul-release coating for shafts, struts, etc. |

| Substrates | Steel, Aluminium, Bronze |

| Water types | Salt water, Fresh water, Brackish water |

| Maximum speed | 40 knots |

| Application method | Roller, Brush |

| Coverage rate | Small kit : 7.5Ft2 (0.7㎡) / Big kit : 40Ft2 (3.88㎡) |

| Pack size | Small kit : 315ml (0.665pts) / Big kit : 1750ml (1.85quarts) |